Our bestsellers

Fresh products

ABOUT US

AzureFilm is an additive manufacturing company from Slovenia, with over 30 years of experience in the plastic industry. Our team of experts, in-house production line, and passion for 3D printing enable us to offer top-quality filaments and other products that you need for 3D printing.

Read more

SERVICES

In addition to the wide range of different 3D filament types and colours, we also offer 3D printers, spare parts, colours on demand, private label options, and much more - all together making AzureFilm the right place where you turn your dreams into the 3D reality!

Read moreShop by Brand

Frequently asked questions

What is 3D printing?

3D printing, or additive manufacturing, builds three-dimensional objects from digital models by adding material layer by layer. It allows for complex shapes with efficient material use. Precision and material range have improved, making it a crucial industrial technology.

There are many different 3D printing technologies, but the most popular ones are Fused Deposition Modeling (FDM), and Stereolithography (SLA).

FDM technology is the most popular and affordable. This technology uses 3D printers to create objects with 3D filaments. The filament is fed into a tube that pushes it into a hot extruder. The filament then comes out through a nozzle and is printed layer by layer on the build platform. FDM printers are perfect for beginners but also capable enough for advanced projects.

Learn more about FDM printing here.

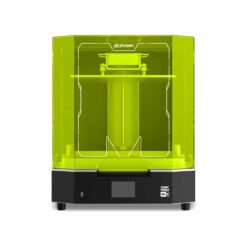

SLA printers use resin materials that harden due to UV illumination. Compared to other printers, SLA technology allows objects to be more detailed. Printing takes longer and the print volume is much smaller. These printers are usually used in the jewellery and medicine industries.

What types of 3D printers are available?

Explore our online shop's extensive 3D printer collection. Whether you prefer FDM or Resin 3D printers, discover the perfect fit for your needs. Our range includes:

- FDM 3D Printers: Fused Deposition Modeling (FDM) technology is suitable for beginners and advanced users. These printers use 3D filaments melted through an extruder to build objects layer by layer.

- SLA or Resin 3D Printers: These printers operate with Stereolithography using resin materials cured by UV light. This technology is ideal for detailed objects and is mostly used in industries like jewellery and medicine.

- 3D Pens: Create three-dimensional drawings in the air using PLA filaments, suitable for children, teenagers, and creative enthusiasts.

What materials can be used in 3D printing?

There are a lot of different 3D printing materials used on the market. Below you can find all the materials we offer.

PLA: Biodegradable and easy to print, ideal for beginners. Comes in various editions, including Silk, Wood, Neon, and more. To know more about PLA filaments, read our blog.

PETG: Combines properties of ABS and PLA, offering solid, heat-resistant, and durable results. Food-grade approved. To know more about PETG filaments, read our blog.

PCTG: An improved PETG with minimal shrinkage and enhanced temperature resistance. To know more about PCTG filaments, read our blog.

ASA: Offers superior UV, water, and chemical resistance, suitable for outdoor appliances and demanding environments. To know more about ASA filaments, read our blog.

ABS PLUS: Known for high impact toughness, thermal resistance, and affordability. Good for applications requiring durability. o know more about ASA filaments, read our blog.

PC ABS: Combines polycarbonate and ABS, providing exceptional mechanical performance, temperature resistance, and chemical resistance. To know more about ABS filaments, read our blog.

Carbon Fiber: Reinforced with carbon fibers, offers exceptional strength and lightweight properties. Suitable for industrial applications. To know more about Carbon Fiber filaments, read our blog.

Nylon: Known for its mechanical, chemical, and flexible properties, making it versatile for various engineering requirements.

Flexible: Offers rubber-like qualities, used in footwear, aerospace, and automotive industries. To know more about Flexible filaments, read our blog.

Support (PVA): Soluble support material that prevents overhangs, dissolving in water to leave the printed object intact. To know more about Support filaments, read our blog.

Here you can find our filament comparison chart to easily see what suits your needs.

Resin: Used for achieving exceptional detail and smooth finishes, particularly in the dental and jewellery industries.

These materials cater to a wide range of applications, offering diverse properties to meet specific 3D printing needs.

How do I design or create 3D printable objects?

Every 3D print begins with a 3D model crafted using modelling software. Several user-friendly modelling programs are available, some of which are free. Here are some popular options:

- Tinkercad: Offering a vast library of files, Tinkercad empowers users to discover suitable shapes and customize them. It serves as an excellent platform for learning 3D modelling.

- SketchUp: Known for its balance between usability and functionality, SketchUp suits a broad range of skill levels, making it an ideal choice for many.

- Blender:While it has a steep learning curve, Blender, as open-source software, is perfect for users ready to tackle complex 3D models.

Alternatively, you can opt for the easier route and download pre-made 3D models for your projects. Several websites and 3D archives offer free 3D models, including:

- Thingiverse: A community and design-sharing platform where you can explore and distribute 3D printable designs.

- Turbosquid: The go-to place for 3D models, offering a substantial selection. You can find many excellent free models by simply searching for "free."

- Free3d: A platform where you can share your 3D assets for free and instantly download others.

Once you have your 3D model (created in modelling software or downloaded from an archive), the next step is to input it into your slicer software.

What is a “slicer” in 3D printing?

Slicers simplify the transition from a 3D model to a printed object by dividing the CAD model into layers and converting it into G-code.

Slicer software also encompasses crucial 3D printer settings like temperature, layer height, and print speed, which are incorporated into the G-code. When the model is transformed into G-code, you can transfer it to your Micro SD card (8GB works well). Ensure the file name contains no more than seven characters.

The 3D printer interprets the G-code and manufactures the model layer by layer, following the instructions within the G-code.

Recommended slicer software for beginners includes:

- Cura: An open-source slicer compatible with nearly any 3D printer, renowned for its user-friendliness, speed, and versatility.

- Simplify3D: In addition to slicing, Simplify3D corrects model issues, offers a preview of the final result, and aids in identifying potential problems.

- Slic3r: An open-source software featuring real-time incremental slicing, 3D preview capabilities, and widespread usage within the 3D printing community.

What are some common problems and troubleshooting tips in 3D printing?

Bad overhangs: Bad overhangs occur when angled or horizontal surfaces sag or droop. To fix this, use support structures provided by slicing software, reduce print speed to allow layers to solidify, enhance cooling, and consider using brims or rafts for better adhesion and support.

Clogged nozzle: Nozzle clogs result from residual filaments, incorrect retraction settings, temperature, debris, or dust. To clear a clogged nozzle, heat it to the recommended filament temperature, extrude the filament, inspect for debris using a flashlight, and use the cold pull technique with a different colour filament until it's clean.

First-layer adhesion: Proper first-layer adhesion prevents print failure, splintering, and warping. Achieve this by levelling the print bed accurately, cleaning it, using adhesives like hairspray or glue stick, adjusting nozzle height, and increasing print temperature for better adhesion.

Stringing: Stringing is caused by low retraction speed, improper cooling, excessive retraction distance, filament diameter settings, or slicer errors. Reduce stringing by adjusting retraction settings, and nozzle temperature, using more fans, calibrating the slicer and filament diameter, and enabling slicer features to reduce stringing.

Warping: Warping involves lifted or deformed print corners due to poor bed adhesion, lack of support, thermal stresses, or inadequate cooling. Prevent warping by using adhesive aids, an enclosure, or a heated print bed with proper levelling, employing brims or rafts for stability, choosing low-warping filaments, and adjusting print speed and temperature.

If you want to know more about how to solve and troubleshoot 3D printing problems, read our blog about the 5 most common 3D printing issues and solutions.

New

New